Pharmaceutical medications can save lives, but taking them as prescribed, especially among people with chronic illnesses, can be challenging for a variety of reasons. Improving medication adherence could reduce poor health outcomes, hospitalizations, and preventable deaths, while reducing healthcare costs in up to 300 billion dollars a year only in the United States.

One possible way to increase adherence is to reduce how often a person needs to take their medication. This can be achieved using a controlled release system, in which a single injection contains a drug that is continuously released into the body over a prolonged period. Unfortunately, many controlled release systems deliver a substantial portion of their payload right after the injection, which can result in inconsistent drug dosing: more drug is released initially (potentially resulting in toxicity) and less drug is released over time (potentially at a dose too small to be effective). A system that could release discrete doses at specific times could revolutionize the way medications are administered, from multi-dose vaccines to daily medications.

In response to this challenge, researchers at Rice University have developed PULSED (for particles uniformly liquefied and sealed to encapsulate drugs). His method, recently reported in Advanced materials, creates drug-filled microparticles that can be engineered to degrade and release their therapeutic payload days or weeks after injection. By combining multiple microparticles with different degradation times in a single injection, researchers could develop a drug formulation that delivers many doses over time.

“As a field, we continually seek to develop effective and efficient drug delivery systems that maximize therapeutic benefit and minimize side effects, which can ultimately improve medication adherence,” said Luisa Russell, Ph.D., program director of the Division of Discovery Science and Technology at the National Institute of Biomedical Imaging and Bioengineering (NIBIB). “With multiple doses combined into a single treatment, the controlled release system described here could transform the therapeutic landscape, potentially eliminating the need for frequent medication administration, both at home and in the clinic.”

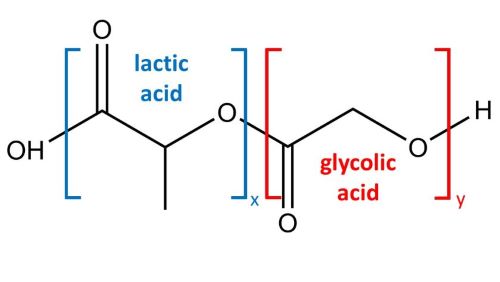

PULSED microparticles are composed of PLGA, or poly(lactic-co-glycolic acid), a polymer commonly used in several FDA-approved devices. PLGA is made up of repeating units of lactic acid and glycolic acid, two molecules found naturally in our body. By extending the overall length of the polymer, modifying the ratio of lactic acid to glycolic acid, and “capping” the end of the polymer with different molecules, researchers can determine how long it takes for PLGA to disintegrate (and thus release its therapeutic payload). “In our case, we can combine populations of microparticles with different PLGA compositions, each releasing their full contents at a different time,” explained study senior author Kevin McHugh, Ph.D., an assistant professor at Rice University. “This allows us to achieve multiple launch events at specific, predetermined times.”

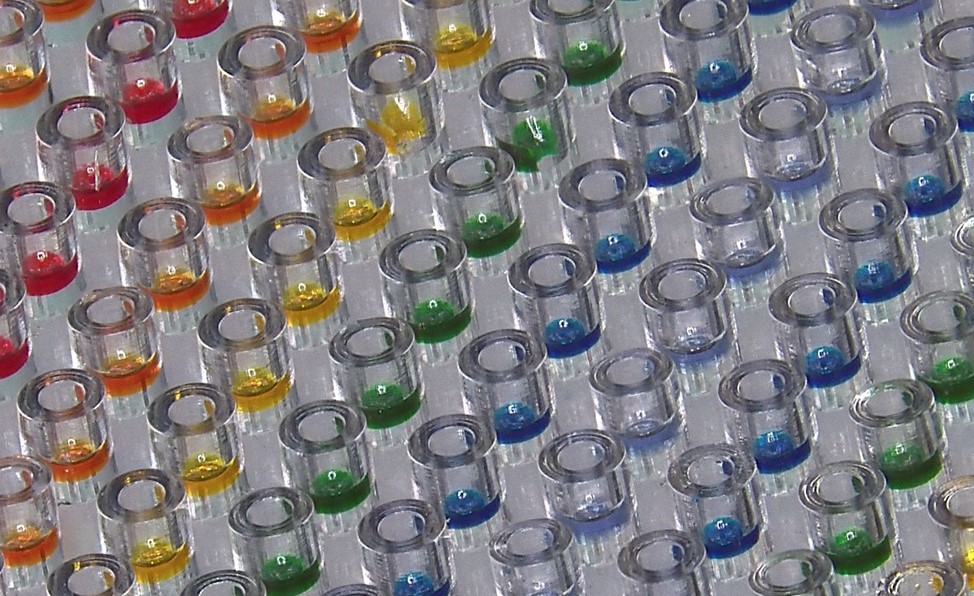

Here’s how drug-loaded microparticles are made: Heated semi-liquid PLGA is pressed into a mold and then cooled, solidifying into hollow cylinders with an opening at the top. The core of each microparticle is filled with a therapeutic filler and then the top of the microparticles is heated, causing the PLGA to melt and flow over the opening to seal the drug inside. The initial particles the researchers developed were 400 micrometers in diameter (for reference, the thickness of a dime is about 1350 micrometers).

As a first step, the researchers filled four different PLGA microparticle shells with dextran (a type of sugar) labeled with a fluorescent molecule, allowing them to easily visualize and measure cargo release. They incubated the microparticles in a body temperature buffer to mimic real-life conditions and found that the microparticles released their contents at staggered intervals, ranging from approximately eight to 31 days, depending on the PLGA formulation. Importantly, the researchers found that each microparticle formulation released its payload rapidly, emptying 75% of the dextran over a period of approximately one to three days. They obtained similar results when they repeated the experiments in mice.

“While we extended the degradation time of the microparticles to approximately five weeks in this study, we have only begun to modify the PLGA compositions to further extend their degradation times and subsequent drug release,” McHugh said. “Based on our previous work with other systems, we are confident that by changing the length of the PLGA and the proportions of the components, we could extend the launch to six months and probably much longer.”

After the researchers optimized their microparticle manufacturing process, they needed to ensure that a drug was still viable once locked inside. Many drugs, especially biological agentsThey are developed using living components, they are sensitive to heat, which researchers use to seal their microparticles. What’s more, the researchers wanted to be sure that long-term storage within the human body (conditions that heat and acidify the microparticles) would not negatively affect the drug. They encapsulated bevacizumab (an FDA-approved antibody used to treat various types of cancer) in their microparticles along with different types of excipients (inactive drug stabilizers) and evaluated the activity of the drug. With the right combination of excipients, the microparticles released bioactive and viable bevacizumab, even after weeks in simulated body conditions.

Finally, the researchers wanted to go further and further miniaturize their microparticles. While the original particles could easily flow through an 18-gauge needle, which is typically used for things like drawing blood, smaller needles are preferred for pediatric vaccines and insulin delivery, typically ranging from 22 to 31 gauge. Using a smaller mold and the same manufacturing method, the researchers were able to shrink the microparticles down to a diameter of 100 micrometers. The carrying capacity of these tiny microparticles is 50 times less than the original microparticles, but they could be used with even the smallest needles in common use, McHugh said. Future work will include evaluation of the decay time and charge release of these miniaturized particles.

“Routes of drug administration are often underestimated in the field of pharmaceutical medicine,” McHugh said. “Our study, although still in an early stage of development, could reshape the way routine vaccines and recurrent medications are administered, ultimately improving medication adherence and human health.”

This research was supported by grants from NIBIB (EB031495 and EB023833) along with grants from the National Science Foundation (NSF; grants 1842494 and 2236422) and the Texas Cancer Prevention and Research Institute (RR190056).

This Science Highlight describes a basic research finding. Basic research increases our understanding of human behavior and biology, which is critical to promoting new and better ways to prevent, diagnose, and treat diseases. Science is an unpredictable and incremental process: each research advance builds on past discoveries, often in unexpected ways. Most clinical advances would not be possible without knowledge of fundamental basic research.

Study reference: Graf TP, Qiu SY, Varshney D, et al. A scalable platform to manufacture biodegradable microparticles with pulsatile drug release [published online ahead of print, 2023 Mar 2]. Adv Mater. 2023;e2300228. doi:10.1002/adma.202300228