What if a doctor could 3D print something? through your skin, building an implant or replacement organ beneath layers of tissue? The world of medicine would be transformed: a host of surgical procedures, carrying a variety of risks, could be performed without ever picking up a scalpel.

An NIH-funded collaborative team is working to make this Star Trek-like fiction a reality. Your work, published today in Sciencedescribes a method for printing biocompatible structures through thick, multi-layered tissues. The beginning? Focused ultrasound, combined with a novel ultrasound-sensitive ink.

“Focused ultrasound has been used for decades to treat a wide variety of conditions, underscoring its safety and utility as a clinical tool,” said Randy King, Ph.D., program director of NIBIB’s Division of Applied Science and Technology. “This potential new application, based on years of technological advances, could lay the foundation for something previously considered impossible: 3D ultrasound printing through tissue.”

Using ultrasound principles for 3D printing

Some 3D printing techniques use light (a form of energy) to trigger the solidification of an “ink,” which is often composed of a liquid substance, such as resin or plastic. Light, however, does not travel well through the skin and organs, and is scattered as it passes through them. In order to successfully “print” through biological tissues, a different energy source would be needed.

Enter the ultrasound. Compared to light, ultrasound waves can travel much further through tissues, sending energy far below the surface. By administering an ink that could solidify through interactions with ultrasound waves, a doctor could potentially build biologically relevant structures within the human body, all without making an incision.

“Our technology is based on the sonothermal effect, which describes the temperature increase that occurs due to the absorption of ultrasound waves,” explained the study’s senior author, Junjie Yao, Ph.D., associate professor of biomedical engineering at Duke University. “If we can precisely control the temperature rise by focusing ultrasound waves, we can guide the solidification of the injected ink, even through layers of tissue.”

The ink is made with four components: a compound that helps absorb ultrasound waves, a microparticle that helps control viscosity, a polymer that provides structure, and a salt that absorbs heat to trigger solidification. “The individual components of bioink are not new; in fact, they have been used for many years in biomaterials applications,” said the study’s senior author, Y. Shrike Zhang, Ph.D., an associate professor and associate bioengineer at Harvard Medical School and Brigham and Women’s Hospital, respectively. “The key was combining these ingredients, in the right proportions, which allowed us to create an ink that can solidify quickly when interacting with ultrasound waves without dispersing.”

From principle to proof of concept

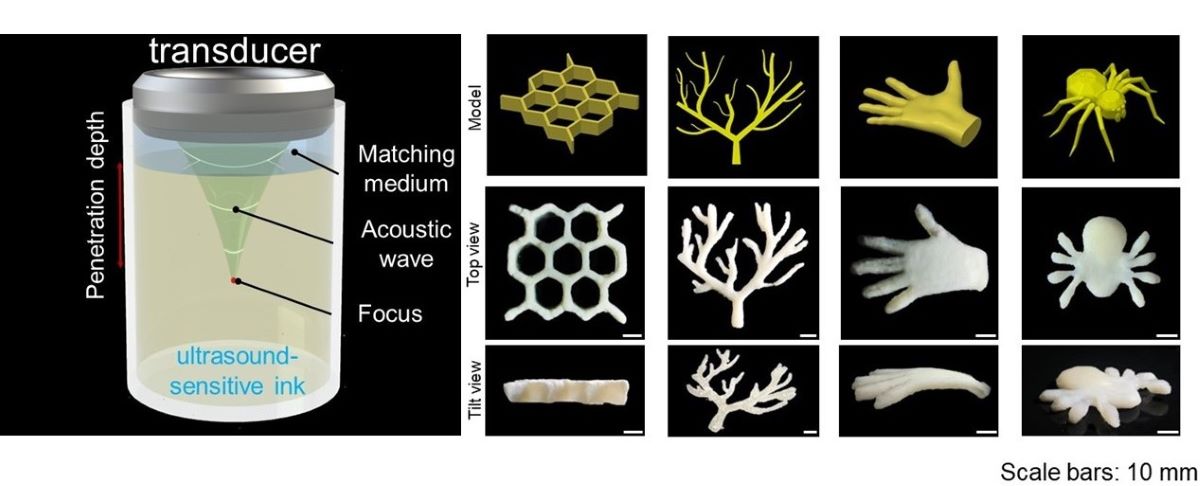

To start, the researchers wanted to see if they could create 3D shapes using their ultrasound technique. They suspended a focused ultrasound transducer over a chamber filled with their new ink. Between the transducer and the ink was a “matching medium”, a substance used in most ultrasound methods that ensures efficient transmission of ultrasound waves. Using a computer program to precisely control the intricate 3D movements of the ultrasound transducer, the researchers were able to create a variety of different structures at different depths within the ink chamber. These structures had a variety of sizes and geometric complexities and included objects such as a multi-layered honeycomb, a branching vascular network, and complex patterns that resembled a hand or a spider.

Next, the researchers wanted to determine if their technique could be used to print through biological tissues. They placed pig tissues of different thicknesses (up to 17 millimeters) on top of the ink-filled chamber. With the transducer positioned above, the researchers directed ultrasound waves through the tissue to the chamber below. They successfully printed a variety of different structures across several different types of tissues, including a pig liver and a pig phantom tissue that was composed of multiple layers (such as skin, fat, and muscle).

To mimic a real-world procedure, the researchers performed a simulated surgery using an ex vivo goat heart. Using a catheter, the researchers injected their ultrasound-sensitive ink into the left atrial appendage, a sac-like structure in the heart where blood clots can develop. Through the wall of the goat heart, the researchers used ultrasound waves to solidify the ink, effectively sealing this area of the heart. This procedure, called left atrial appendage closure, may require open-heart surgery and is sometimes performed in patients with atrial fibrillation who are at higher risk for stroke.

These initial experiments demonstrate that this proof-of-concept printing method has the potential to convert highly invasive surgical procedures into safer, less invasive ones. “Our technique could provide an unconventional route to truly minimally invasive medicine that previously seemed almost impossible,” Yao said.

Looking forward

This focused ultrasound printing technique can require high levels of energy, which has the potential to overheat surrounding tissues. To combat this, the researchers built a high-intensity confocal ultrasound printer. This system uses two ultrasound transducers that are aligned in a transverse beam pattern, allowing the two ultrasound wavefronts to overlap. This design not only reduces the power required for each transducer, but also improves the resolution and speed of the ultrasound printer.

“We will continue to modify our technique to increase its safety and efficiency, seeking to adapt our technology for different medical uses,” Zhang said. “While we believe our method has the potential to enable a variety of minimally invasive procedures, it remains a prototype technology that will require further optimization before it can be evaluated in humans.”

Yao and Zhang, who have known each other since graduate school, have spent the last few years working together on their ultrasonic 3D printing technology. “Our multi-year collaboration gave us the opportunity to create a new technique that combines our unique perspectives: ultrasound imaging and biochemistry,” Yao said. “We could not have created this technology without each other, highlighting the unique possibilities that can arise from interdisciplinary partnerships.”

This research was supported by grants from the NIH, including NIBIB (R21EB025270, R21EB027981, R21EB027304, R01EB028143, R21EB027981, and R01EB031629); the National Heart, Lung, and Blood Institute (R01HL153857, R01HL165176, and R01HL166522); the National Institute of Neurological Disorders and Stroke (RF1NS115581 and R01NS111039); and the National Cancer Institute (R01CA282451). Other funding includes grants from the National Science Foundation.

This Science Highlight describes a basic research finding. Basic research increases our understanding of human behavior and biology, which is critical to promoting new and better ways to prevent, diagnose, and treat diseases. Science is an unpredictable and incremental process: each research advance builds on past discoveries, often in unexpected ways. Most clinical advances would not be possible without knowledge of fundamental basic research.

Study reference: Xiao Kuang et al. Self-enhanced sonic inks enable deep-penetrating acoustic volumetric printing. Science 3821148-1155 (2023) DOI:10.1126/science.adi1563

The graphs seen here and on the NIBIB website have been adapted from figures found in the Science publication.