Toray has begun providing prototype samples to customers to develop decorative and performance materials for various applications such as automobiles, construction, electrical and electronics, and daily needs. The company will move forward with technical evaluations that fit customer needs.

Toray Industries has developed a recycling technology that breaks down thermoset-based CFRP while retaining more than 95 percent of the fiber’s strength, reducing CO₂ emissions by half. The process enables the production of high-quality recycled carbon fiber nonwoven fabrics with functionality and aesthetic appeal, supporting diverse applications and promoting circular economy goals.

CFRP applications include aircraft and wind turbines. Chemical recycling as a reducing agent in steel furnaces is gaining ground for CFRP recycling. Technologies are emerging that pyrolyze CFRP waste at high temperatures to recover and reuse fibers, and the market is expanding particularly for injection molding applications. To expand applications, technology that can suppress thermal damage to recycled carbon fibers and control resin waste and that can be applied to various types of CFRP waste is needed.

Toray applied its accumulated experience in organic synthesis and polymer polymerization to innovate a decomposition agent that decomposes degradation-resistant cross-linked three-dimensional thermoset resins at lower temperatures than conventional methods. The company used this agent to break down CFRP waste from airplanes, wind turbines, automobiles and other sources. The recycled carbon fiber from this process retains more than 95% of the single-fiber tensile strength of virgin petroleum-derived carbon fiber. Toray expects carbon dioxide emissions from this technology to be less than half those of manufacturing virgin carbon fiber.

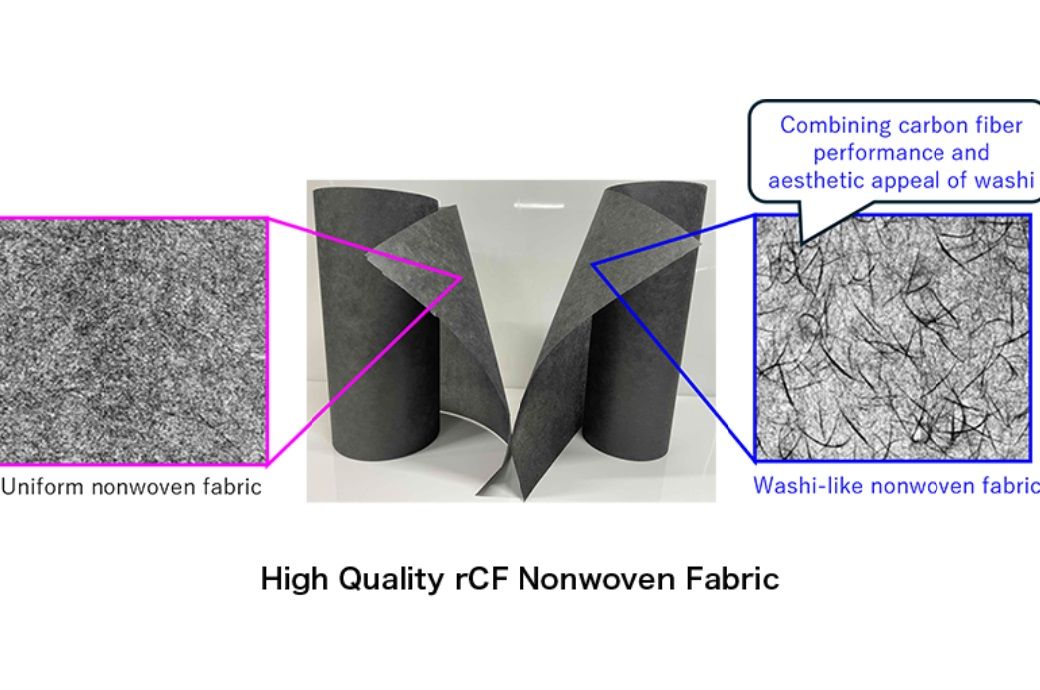

The recycled carbon fiber obtained with this technology is stronger than its conventional counterparts and minimizes fiber breakage in post-processing. Its low resin residue and excellent surface quality allow processing for more diverse applications. In particular, efforts to disperse short fibers and process them into sheet-like nonwoven fabrics have been successful. The recycled carbon fibers produced with this technology exhibit controllable water dispersibility, allowing the fabrication of uniform nonwoven structures, as well as those with a distinctive texture reminiscent of washi (traditional Japanese paper). This fabric combines the functionality of carbon fiber, including radio frequency shielding and thermal conductivity, with the aesthetic appeal of washi. Toray aims to expand the applications of this new material in many industries.

This innovative fabric is found in the interior and exterior components of the concept car (vision model) that Mazda Motor Corporation will exhibit at the Japan Mobility Show in Tokyo Big Sight from October 30 to November 9.

Toray developed its recycling technology and carbon fiber nonwoven fabric processing technology as part of a fiscal year 2024 to 2025 Ministry of Environment program to promote the establishment of a circular and decarbonized economy.

One of the objectives of the Toray Group’s Sustainability Vision for 2050 is to contribute to “a world where resources are managed sustainably.” The company will continue to advance R&D to help create a circular society, in line with its corporate philosophy of “contributing to society by creating new value with innovative ideas, technologies and products.”

Note: The headline, ideas and image of this press release may have been refined by Fibre2Fashion staff; the rest of the content remains unchanged.

Fiber2Fashion (HU) News Desk