A new technique funded by NIBIB and developed by researchers at the University of Minnesota allows 3D printing of hydrogel-based sensors directly on the surface of organs, such as the lungs, even as they expand and contract. The technology was developed to support robot-assisted medical treatments.

The research team included mechanical and computer engineers led by Michael McAlpine, Ph.D., Kuhrmeyer Family Professor of Mechanical Engineering. “Along with a robot’s ability to help a surgeon remove a tumor from a lung, for example, this technology could 3D print a sensor on the surface of the lung to monitor how well it works during and after the procedure,” McAlpine explained.

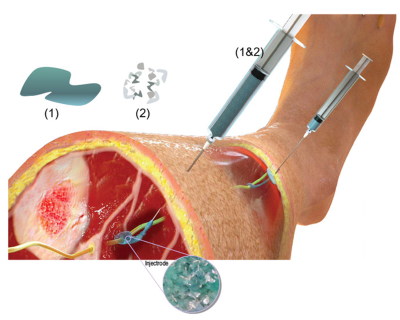

Researchers hope that this innovative technology will facilitate the 3D printing of various functional devices “on and within the human body.” Examples include electrode arrays that interact with the nervous system to treat pain, bioscaffolds with engineered cells that can regenerate tissue, and the efficient and precise application of surgical glues and skin grafts.

“McAlpine and colleagues continue to advance the biomedical applications of 3D printing,” said Michael Wolfson, Ph.D., director of the NIBIB Program in Bionic and Robotic Systems. “They constantly identify biomedical problems that need technological solutions and then design and build sophisticated systems to meet the need. And because this research is not just about innovative engineering, they also demonstrate that the technology works in realistic biological systems.”

A key to making the technology work was the use of motion capture technology, which is similar to that used in movies and video games. Filmmakers use the technique to track moving elements in a scene to seamlessly insert special effects, or on actors to turn them into CGI characters. That type of “closed-loop” tracking allowed us to add a new degree of freedom in 3D printing: successfully printing a sensor on an expanding biological surface without damaging the organ.

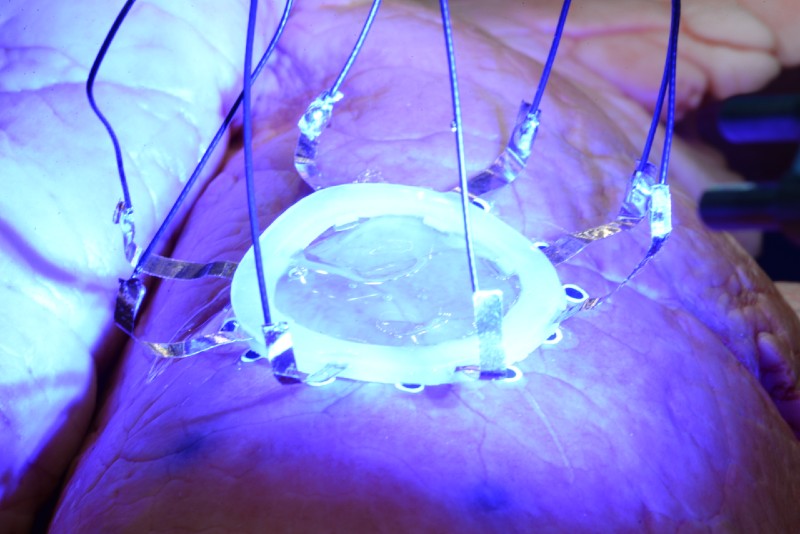

After fitting the new system on a balloon as it inflated and deflated, the team moved on to printing on an animal lung in the lab while rhythmically pumping air into it to simulate breathing. A special hydrogel was printed with electrodes around its perimeter to form an electrical impedance tomography (EIT) sensor map. The device can stretch with the movement of the surface it sits on, such as when the lungs inhale and exhale, movement that the sensor can transmit electronically to track real-time tension on the lung surface as it expands and contracts.

“Measuring lung flexibility with the EIT sensor is just one example of remotely measuring the health of an organ using a sensor printed on its surface,” McAlpine explained. “We plan to develop different types of sensors that could be adapted to different organs, such as a sensor printed on a human heart to monitor cardiac function.”

Technology could also be a useful tool in the care of patients with COVID-19. “We are starting to learn a lot about the effects of COVID-19 on the human body,” McAlpine said. “Technology like this could be used to monitor changes in respiratory function during and after coronavirus infection.”

The study was published in the journal Science Advances.1. The work was supported by Medtronic plc (for sensor development) and the NIH National Institute of Biomedical Imaging and Bioengineering under award number DP2EB020537.